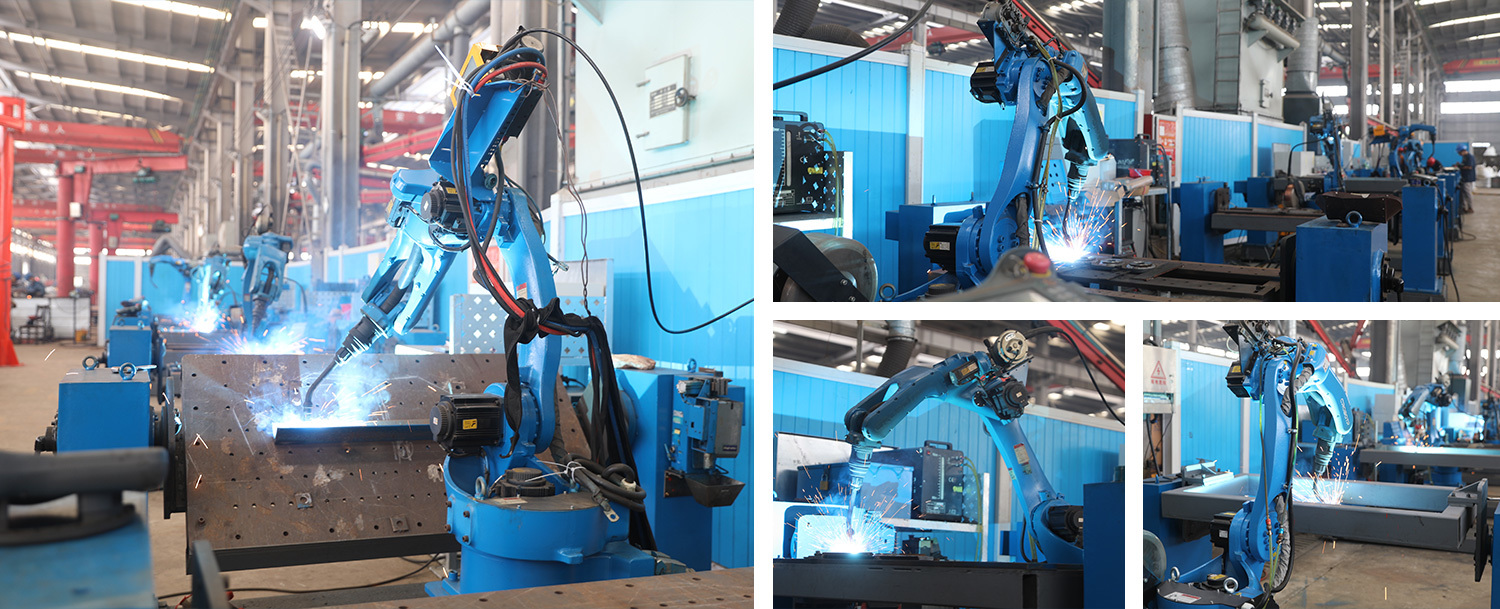

Welding Robot

Hot-dip Galvanizing

Hot-dip galvanizing is a metal anti-corrosion process in which the steel substrate is immersed in a molten zinc solution to achieve a uniform and dense layer of zinc attached to the metal surface. This process significantly improves the corrosion resistance of steel and extends its service life. The hot-dip galvanizing process involves a number of steps, including cleaning, fluxing and dipping, to ensure a strong metallurgical bond between the zinc layer and the substrate. It is widely used in construction, bridges, highway guardrails, electrical fields, etc. Hot-dip galvanizing is not only corrosion-resistant, but also has good electrical conductivity and aesthetics, making it an indispensable surface treatment technology in modern industry.

Personnel Department:86-395-3359799

Purchasing Department:86-395-3338867

E-mail:hnygrsb@163.com

Second Branch Factory: Southeast Corner of Intersection of Qidu Road and Renmin Road, Zhaoling Town, Zhaoling District, Luohe City, Henan Province

Third Branch Factory: North of Silver Pigeon Sixth Base, Songjiang Road, Zhaoling Town, Zhaoling District, Luohe City, Henan Province

Official TikTok

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.